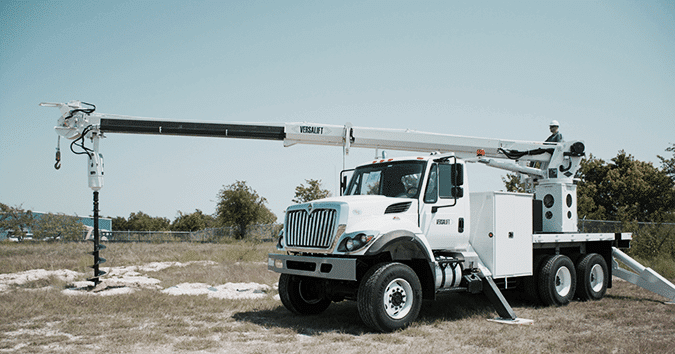

Regular maintenance is vital for ensuring the safety, reliability, and longevity of digger derricks. Adhering to a strict maintenance schedule can prevent costly repairs, minimize downtime, and optimize equipment performance. Neglecting maintenance can lead to safety hazards, decreased efficiency, and premature wear and tear on critical components.

Prioritizing regular maintenance is essential to protect your investment and maintain optimal working conditions. Proper maintenance is crucial for the safe and reliable operation of digger derricks, which are used for lifting, digging, and hoisting operations. Regular inspections and maintenance checks can identify potential issues before they escalate into major problems, reducing the risk of accidents and equipment failure.

By staying on top of maintenance tasks, operators can ensure their digger derrick is safe to operate and will perform as expected when needed.

1. Ensuring Safety and Reliability

Preventing Accidents and Equipment Failure

By adhering to a strict maintenance schedule, you can identify and address potential issues before they escalate into major problems, reducing the risk of accidents and equipment failure. Regular inspections and maintenance checks can help to ensure that all components are in good working order, minimizing the risk of unexpected malfunctions or breakdowns.

Extending the Lifespan of Your Equipment

Regular maintenance is also essential for the longevity of your digger derrick. By keeping all components well-maintained, you can extend the lifespan of your equipment and maximize its value over time. Neglecting maintenance can lead to premature wear and tear on critical components, reducing the overall digger derrick lifespan.

Protecting Your Investment

By staying on top of maintenance tasks, you can protect your investment and ensure that your equipment continues to perform reliably for years to come. Prioritizing regular maintenance is essential for protecting your investment and maximizing the lifespan of your digger derrick.

2. Extending the Lifespan of Your Digger Derrick

Regular maintenance is essential for extending the lifespan of your digger derrick. This heavy-duty equipment is subjected to rigorous use in challenging work environments, making it crucial to keep all components well-maintained. By adhering to a strict maintenance schedule, you can minimize wear and tear on critical components, reducing the risk of premature failure and extending the overall lifespan of your equipment.

Regular inspections and maintenance checks can identify potential issues before they escalate into major problems, allowing you to address them proactively and prevent costly repairs. By prioritizing regular maintenance, you can protect your investment and ensure that your digger derrick continues to perform reliably for years to come. In addition to extending the lifespan of your equipment, regular maintenance can also help to prevent costly repairs and minimize downtime.

By staying on top of maintenance tasks, you can identify and address potential issues before they escalate into major problems, reducing the risk of unexpected malfunctions or breakdowns. This proactive approach can help to minimize downtime and keep your digger derrick operating at peak performance, maximizing productivity and efficiency. By prioritizing regular maintenance, you can minimize the risk of costly repairs and keep your equipment in optimal working condition, reducing the overall cost of ownership over time.

3. Preventing Costly Repairs and Downtime

Regular maintenance is essential for preventing costly repairs and minimizing downtime for your digger derrick. This heavy-duty equipment is subjected to rigorous use in challenging work environments, making it crucial to keep all components well-maintained. By adhering to a strict maintenance schedule, you can identify potential issues before they escalate into major problems, allowing you to address them proactively and prevent costly repairs.

Regular inspections and maintenance checks can help to ensure that all components are in good working order, minimizing the risk of unexpected malfunctions or breakdowns. By staying on top of maintenance tasks, you can minimize downtime and keep your digger derrick operating at peak performance, maximizing productivity and efficiency. In addition to preventing costly repairs, regular maintenance can also help to ensure compliance with manufacturer’s recommendations.

Following the manufacturer’s guidelines for maintenance and service intervals is essential for protecting your warranty coverage and ensuring that your equipment continues to perform reliably. By adhering to a strict maintenance schedule, you can demonstrate that you have taken proper care of your digger derrick, reducing the risk of warranty claims being denied due to neglect or improper maintenance. By prioritizing regular maintenance, you can protect your investment and ensure that your equipment remains in compliance with manufacturer’s recommendations.

4. Compliance with Manufacturer’s Recommendations

Regular maintenance is essential for ensuring compliance with manufacturer’s recommendations for your digger derrick. Following the manufacturer’s guidelines for maintenance and service intervals is crucial for protecting your warranty coverage and ensuring that your equipment continues to perform reliably. By adhering to a strict maintenance schedule, you can demonstrate that you have taken proper care of your digger derrick, reducing the risk of warranty claims being denied due to neglect or improper maintenance.

Regular inspections and maintenance checks can help to ensure that all components are in good working order, minimizing the risk of unexpected malfunctions or breakdowns. By prioritizing regular maintenance, you can protect your investment and ensure that your equipment remains in compliance with manufacturer’s recommendations. In addition to protecting warranty coverage, compliance with manufacturer’s recommendations through regular maintenance can also help to maximize performance and efficiency.

By keeping all components well-maintained, you can ensure that your digger derrick operates at peak performance, maximizing productivity and efficiency. Neglecting maintenance can lead to decreased efficiency and performance, reducing the overall productivity of your equipment. By staying on top of maintenance tasks, you can ensure that your digger derrick continues to perform reliably and efficiently, maximizing its value over time.

5. Maximizing Performance and Efficiency

Regular inspections and maintenance checks can help to identify potential issues before they escalate into major problems, allowing you to address them proactively and prevent costly repairs. By prioritizing regular maintenance, you can maximize the performance and efficiency of your digger derrick, ensuring that it operates at peak productivity. In addition to maximizing performance, regular maintenance can also help to ensure that your digger derrick operates safely and reliably.

By keeping all components well-maintained, you can minimize the risk of accidents and equipment failure, protecting both your employees and your investment. Neglecting maintenance can lead to safety hazards and decreased reliability, increasing the risk of accidents and unexpected downtime. By staying on top of maintenance tasks, you can have peace of mind knowing that your digger derrick is safe to operate and will perform as expected when called upon.

Prioritizing regular maintenance is essential for maximizing performance and efficiency while ensuring the safety and reliability of your equipment. Regular maintenance can help to ensure that all components are in good working order, minimizing wear and tear on critical components. Neglecting regular maintenance may lead to safety hazards, decreased efficiency, and premature wear on critical components, resulting in costly repairs or downtime. Therefore, it is crucial to adhere strictly to a regular maintenance schedule to protect your investment and keep your digger derrick in optimal working condition.

Digger Derricks Service and Repairs in Tennessee

In conclusion, digger derricks play a vital role in the utility industry, providing essential support for various tasks such as digging holes for poles, lifting heavy materials, and performing maintenance on overhead lines. Their versatility and efficiency make them indispensable tools for utility companies across Tennessee and beyond.

When it comes to maintaining the performance and safety of these machines, regular service and repairs are crucial. This is where ML Utilities steps in, offering specialized services tailored to the needs of digger derricks and other utility trucks. With a team of highly skilled service technicians who possess extensive backgrounds in working with a wide range of makes and models, ML Utilities ensures that your equipment remains in optimal condition.

Whether you require routine maintenance or urgent repairs, we are committed to providing reliable solutions that keep your operations running smoothly. Our expertise not only enhances the longevity of your equipment but also contributes to the overall safety and efficiency of your workforce.